Standard Test Method (ASTM D5) for Penetration of Bituminous Materials lab report

EXPERIMENT NAME: Standard Test

Method (ASTM D5) for Penetration of Bituminous Materials.

Purpose of the Test

Consistency of a bituminous material expressed as the distance

in tenths of a millimeter that a standard needle vertically penetrates a sample

of the material under known conditions of loading, time, and temperature.

1.

The penetration test is using as a measure of the consistency.

Greater values of penetration determine softer steady.

2.

The test is widely used all over the world for classifying bituminous

materials into different grades.

3.

Rely on upon the weather condition and types of construction,

bitumen of various penetration grade are using. Generally using grade are

30/40, 60/70 and 80/100.

4.

In warmer regions, lower penetration grades are preferred and in

colder regions bitumen with higher penetration values are used.

5.

The test is not intended to estimate steady of softer materials

like cut back which are usually graded by vise intentional ossify test.

GRADES OF BITUMEN:

Bitumen is usually characterized in the following three types of

grades;

1.

Viscosity grades

2.

Penetration grades

3. Density

grades

APPARATUS

·

Penetration test Apparatus

·

Penetration Needle

·

Sample Container — A metal or glass cylindrical,

flat-bottom container of the following dimensions shall be used.

·

Water Bath — A bath having a capacity of at least 10 Liter and capable of

maintaining a temperature of 25 ±

0.1 °C or other temperature of test within 0.1 °C.

·

Timing Device hand operated penetrometers any convenient Stop watch required.

·

Thermometers temperature 0° to 50°C with subdivisions maximum scale

error 0.1°

,

PREPARATION OF TEST SPECIMEN

Heat the sample wcarefully, stirring when it possible to withstand

local over heating, until it has become enough fluid to effuse. In no other

case should be the temperature be increased to more than 90 °C up expected soft

point for petroleum asphalt. Do not heat specimen for more than thirty minutes.

Avoid incorporating bubble into the specimen.

Effuse the specimen into the specimen jar to

the depth such that, when cooling to the temperature of test, the depth of the

specimen is at least 10 mm higher than

the depth to which the needles expected

to penetrate. Effuse 2 separate portions for each difference in test situation .

Loosely cover each container as a protection against dust

(covering with a lipped beaker) and allow cooling in air at a temperature

between 15° and 30 °C

for 1 to 1.5 hours for

the small container and 1.5 to 2 hours

for the taller.

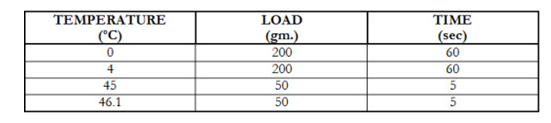

TEST CONDITIONS

Where the situation of this

test are not specific mentioned, to the temperature, load, and time are

understand to be 25 °C, 100 gm,

and five seconds, respectively. Other situation are may be using for

special test, such as the following:

in such cases the specific situation of test will be reported.

REPORT

Report to the closely

full unit the average of 3 penetration whose values didn`t various more

than the following table :

PROCEDURE

Ø Examine the needle holder and

guide to establish the absence of water and other extraneous materials. Clean a

penetration needle with toluene or

other suitable solvent, dry with a clean cloth, and insert the

needle into the penetrometer. if not, otherwise specific place to the fifty(50) gm weight above the needle,

making the total weight 100 ± 0.1 gm.

Place the sample jar in the transfer

dish, cover the container fully with water the constant temperature bath and the place in

to transfer dish on the stand to the penetrometer.

Ø

Position the needle by slowly lowering it until its tip just

makes contact with the surface of the sample. This is accomplished by the

taking of actual needle tip into the contact with its image reflected on the

surface of the specimen from properly

placed source of the light. Either annotation the reading of the penetrometer

dial the pointer to 0(zero). Quickly leave the needle holder for the specific

period of the time and adjust apparatus to

measure the distance penetrated in tenths of a millimeter. If the vas is moving, omit the result.

Ø Make at least three

determinations at points on the surface of the sample not less than 10 mm from the side of the

container and not less than 10 mm apart. If the transfer dish is used, return

the sample and transfer dish to the constant temperature bath between

determinations. Use a clean needle for each determination. If the penetration

is greater than 200, using at least 3 needle for leaving them into specimen

until the3 determination completed.

If the differences are exceeded repeat the test using second sample.

If the appropriate tolerance is again exceeded ignore all result

and repeat the test completely.

Nice Post!!

ReplyDeletePlease look here at Bitumen Emulsion